In an era where every detail counts, your brand’s identity is no longer confined to logos or packaging—it speaks through subtleties. One of the most powerful yet understated tools in fashion and accessories? The leather label tag. More than just a functional component, it's a silent ambassador of craftsmanship, heritage, and authenticity.

When the Tag Becomes Your Brand’s Silent Ambassador

Consider this: a hand-stitched bag with flawless construction, but finished with a flimsy paper label. Instantly, the perception shifts. Quality feels compromised. Now imagine replacing that with a richly textured, embossed leather tag—soft to the touch, subtly branded, enduring over time. Suddenly, the product tells a story of care, intention, and value.

Fashion houses like independent designers in Milan to emerging streetwear labels in Seoul have discovered that customers don’t just buy products—they buy narratives. A well-crafted leather label reinforces trust, elevates perceived value, and fosters emotional loyalty. It becomes part of the unboxing experience, a tactile memory that lingers long after purchase.

Going Straight to the Source: Rethinking Supply Chain Logic

For years, brands relied on distributors and middlemen to source custom labels. But behind those convenient catalogs lie hidden costs—markup layers, delayed communication, and rigid customization limits. By cutting out the intermediaries and working directly with manufacturers, brands gain control.

Direct-from-factory partnerships mean clearer pricing, faster feedback loops, and unmatched flexibility in design iteration. Whether you're tweaking font depth or adjusting leather thickness, real-time collaboration ensures precision. Transparency deepens too—knowing exactly where and how your labels are made builds confidence in both production ethics and final output.

The Art of Customization: From Raw Hide to Signature Detail

Creating a leather label isn't simply about stamping a logo. It’s a blend of material science and artisan technique. Modern manufacturers offer a range of finishes: deep blind debossing for minimalist elegance, vibrant foil stamping (gold, silver, matte black), edge painting in custom Pantone shades, and even laser engraving for intricate detailing.

Material choice sets the tone. Want earthy authenticity? Go for vegetable-tanned leather. Seeking durability with lower environmental impact? Recycled or bio-based synthetics deliver performance without compromise. Each option aligns with a different brand ethos—be it rustic luxury, urban minimalism, or eco-conscious sophistication.

Footwear brands use slim profile tags sewn into linings; handbag makers favor larger, statement pieces with dual-sided branding; high-end apparel lines opt for soft lambskin labels with micro-stitching. Every industry has its signature style—and today’s manufacturers make it easy to tailor yours.

Start Smart: Why Leading Brands Begin with Samples

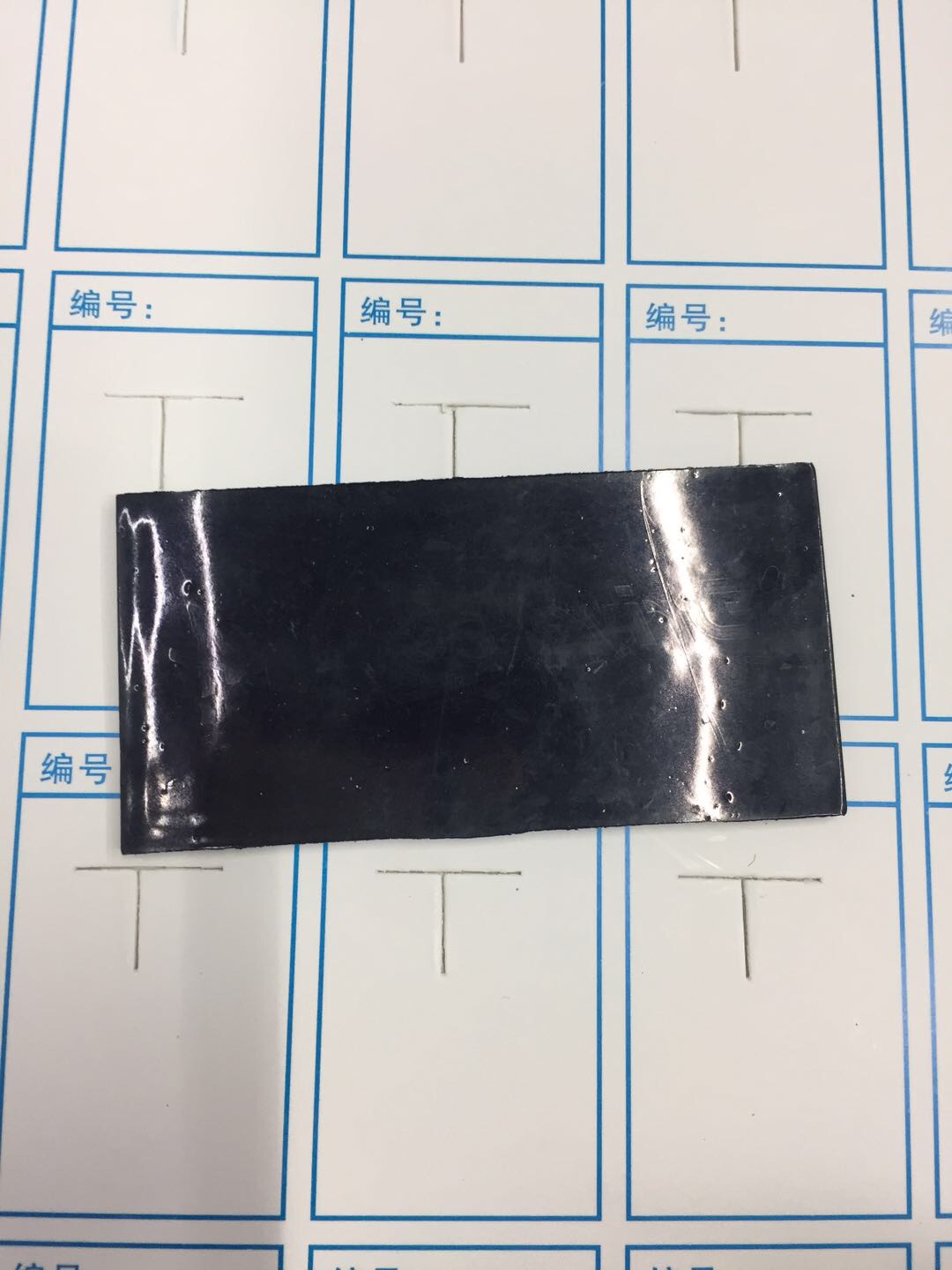

Before committing to mass production, smart designers request physical samples. This crucial step allows evaluation of color accuracy, texture, structural integrity, and wear resistance under real conditions. Is the gold foil peeling after simulated wash cycles? Does the thread hold after repeated flexing?

A reliable manufacturer provides detailed sample kits showing variations in finish, font size, and attachment method. Look closely at stitch density, consistency across multiple units, and registration accuracy. These small details predict large-scale success. Iterative sampling not only prevents costly errors but also empowers creative refinement until perfection is achieved.

Scaling with Confidence: Mastering the Balance of Volume, Cost & Speed

Bulk ordering brings economies of scale, but MOQs (Minimum Order Quantities) shouldn’t dictate strategy. Forward-thinking manufacturers now offer flexible tiers—from 500 to 50,000+ units—without sacrificing unit cost efficiency.

Planning is key. Align label production with seasonal collections or product launches. With optimized workflows and automated cutting/embossing lines, top-tier factories can deliver orders in as little as 10–15 days from final approval. That speed translates into agility—getting your product to market faster, staying ahead of trends, and reducing inventory pressure.

Building Trust: How to Spot a Truly Reliable Manufacturer

Not all suppliers are created equal. Distinguish between brokers who outsource and true manufacturers with in-house facilities. Check for advanced machinery (hydraulic presses, digital die-cutters), certifications (ISO, SEDEX), and sustainable practices. Client testimonials and case studies reveal reliability beyond promises.

Ask critical questions: Do they own their tooling? Can they provide batch traceability? What happens if there’s a defect? A trustworthy partner stands by their work and offers solutions, not excuses.

Sustainability in Every Stitch: The Rise of Eco-Friendly Leather Labels

Modern consumers demand responsibility. Brands responding with water-based dyes, chrome-free tanning, and FSC-certified backing cards signal integrity. Some manufacturers now offer carbon-neutral production options and biodegradable alternatives—meeting both regulatory demands and ethical expectations.

Designing for Growth: From Studio to Global Reach

As brands expand, so should their labeling systems. Modular designs allow consistent branding across product lines. Multi-language tags support international markets. QR codes or NFC-enabled smart labels open doors to digital storytelling and anti-counterfeiting measures—bridging physical craftsmanship with digital trust.

Partners Beyond Production: Co-Creating the Future of Branding

The best manufacturers don’t just fulfill orders—they collaborate. Their technical teams suggest improvements in legibility, durability, or aesthetic balance early in the design phase. Together, brands and producers innovate: developing new textures, integrating sustainable materials, or pioneering hybrid label formats.

When you choose to order bulk custom leather labels directly from the source, you’re not just buying a component—you’re building a partnership rooted in quality, transparency, and shared vision.